Tough as Nails: Nailing Down the Different Types, Collations and Recommendations.

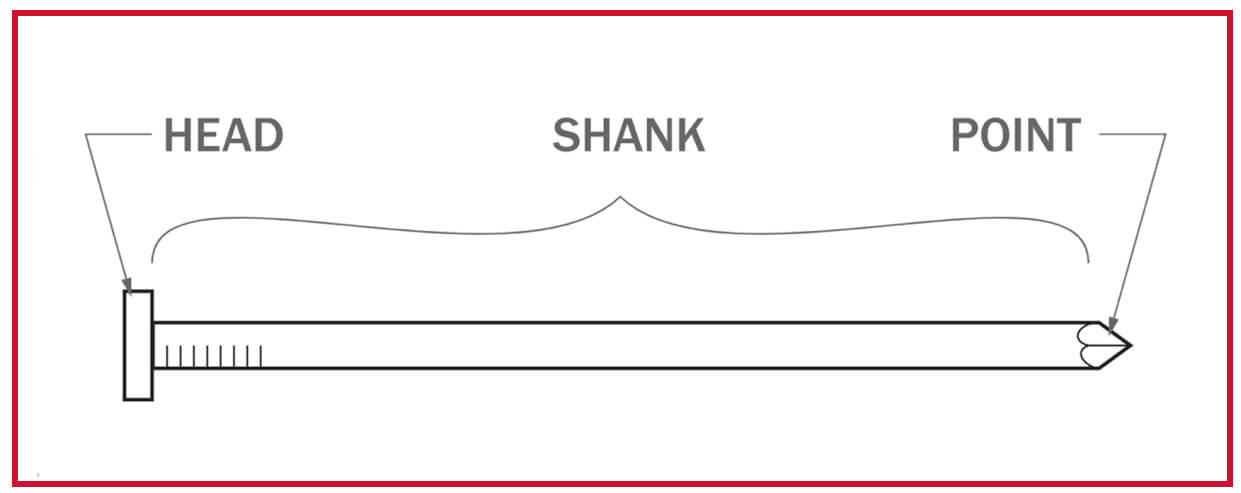

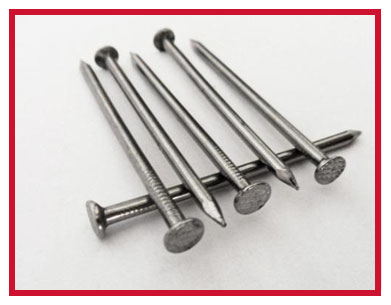

As you might guess, nails are ancient technology going way back to the 1800s when you had to heat square iron rods and hammer the sides to form a point. Nowadays, modern nails are much easier, faster, and cheaper to produce. As compared to their predecessors which were restricted to square shanks and hammered heads, nails today come in different designs giving them different capabilities and applications. The three main parts of a nail are: a head that allows you to drive it into the workpiece and helps prevent the nail from pulling through, a shank/shaft that gives it the holding power needed to secure the workpiece together, and lastly a sharp point that helps penetrate the workpiece. In this article, we’re going to break down the different types of nails, angles, collation types, and applications where they are used

Key Nail Elements

The Head

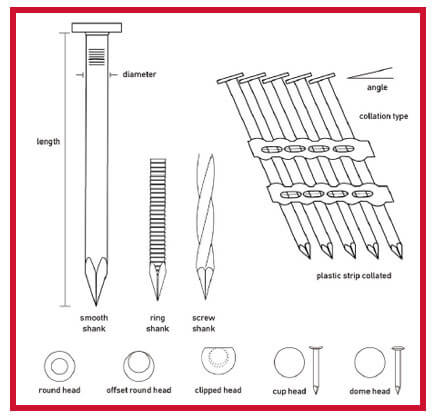

The head of the nail as you expect is the part that is struck by the driver of the tool or by a hammer to drive it into the workpiece. These heads can either come shaped round, clipped, or offset.

- Round head nails are often used for more general purposes and are the most widely accepted nail head type according to most building codes. With a full round head, it allows for an easier hammer contact however, they typically hold fewer nails in a strip.

- Clipped head nails are designed for use in strip nailers (more about that later), they come tightly joined together in strips together in a line. Because they are so close together the Dshaped heads allow the heads to not overlap each other while allowing room for each to be hit by the driver. For these unique types, you’ll need to check your local building codes to see if this can be used.

- Offset head nails serve the same purpose as clipped nails, however, they come with a full round head but are offset to one side of the shaft. This allows nails to be arranged tightly together in a strip holding more nails with steeper angles of collation.

In addition to the standard framing nails above, there are also finish nails and brads that are used for more delicate work. Their heads are much smaller and rectangular, usually, the same width as their shank but the length of the rectangle is greater than the shank. This gives it some holding power but not as much as round or clipped heads.

The Shank

The shank of the nail is essentially the body of the nail which gives it most of its holding power. As the nail penetrates the wood, the wood fibers press against the shank holding it in place. The Shank is the main part of the nail that can be redesigned into five types which are smooth, spiral, ring, screw and barbed. As you may think, they look exactly as the names imply.

Smooth shank nails are considered the most economical, but they lack holding power compared to others. Due to its smooth outer body, makes an easier drive into the material, these are the you would typically use in basic framing and interior finish work.

Spiral shank and Screw shank are quite similar nails that come in a twisted design almost looking like a drill bit. This rugged design increases the holding power as the wood fibers wrap around its deformed shanks. This threading action increases its frictional force within the wood, needed especially in applications where wood is routinely expanding and contracting due to moisture like in hardwood flooring, decking, and siding. Another big pro for screw shanks is that if you’ve made a mistake or you’re doing repairs, you can easily remove the nail with a screwdriver after being driven in by a nailer.

Barbed shank nails are combined with a large head specifically for roofing in areas of mother nature’s stronger winds. This type of nail is built strong for its purpose and reduces the chances of pops, blow-offs, and leaks especially for the Columbus style roofing system.

Ring shank nails come in a ring punched pattern on its surface. This type arguably has the strongest holding power amongst the others as the nail penetrates the wood, and fibers lock into each groove along the shank. Strong holding power is critical in high wind areas when sheathing roofs and walls or when any plywood to floor joists applications.

Now as shanks become more deformed giving them more holding power, it also takes a greater force to drive it into the material. Traditional nailers are being outmatched by screw shank nails however, energy boosted nailers such as the PN59 Coil Nailer eliminate the wasted time going back to finish the drive with a hammer.

The Point

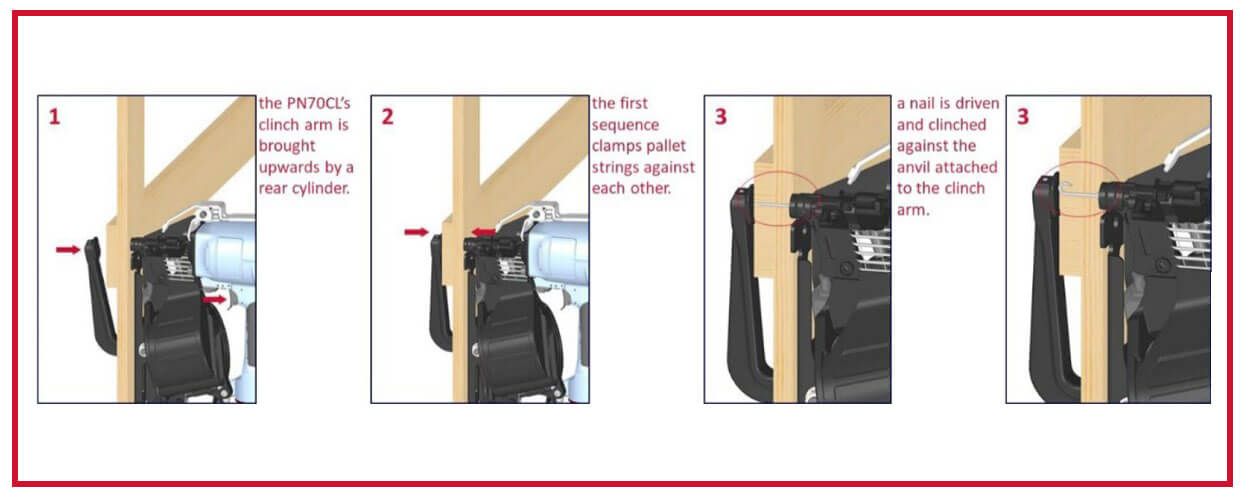

The most common point for nails you’ll find is the standard chisel point, which is quite sharp, giving it the ease of penetration. Points are specially designed to prevent wood splitting or to be bent over (called clinching). The industrial patented PN70CL Clinch Nailer handles nail points that come diagonally cut (as shown below) so that when it hits the built-in metal plate under the wood, it deflects and bends one side, back into the wood. Clinch fastening revolutionized the way strong pallets are repaired.

The Coating

Lastly, let's touch on the protection of resistance to rusting on different finish coatings: Nails are typically coated in a material to prevent rust in areas susceptible to moisture or with treated woods. If not coated, it would be labeled as Bright. These would be used anywhere but outdoors.

On the other hand, the best way to prevent nails from corroding is with a galvanized coating. The more the merrier saying applies to this type of coating as the thicker the coat the better the protection level is. Depending on the local building codes, you would be required the use a specific level of coating on the application you intend to do.

Stainless steel, while it may not be considered a coating, it still resists corrosion as effectively but at a higher cost.

Nail Collation Types and Angles

Gone are the days of carrying boxes of nails around and putting them in place one by one. Today’s practical tools are designed for high-speed, high-volume operations so fasteners come in either coils or sticks collated together in different materials.

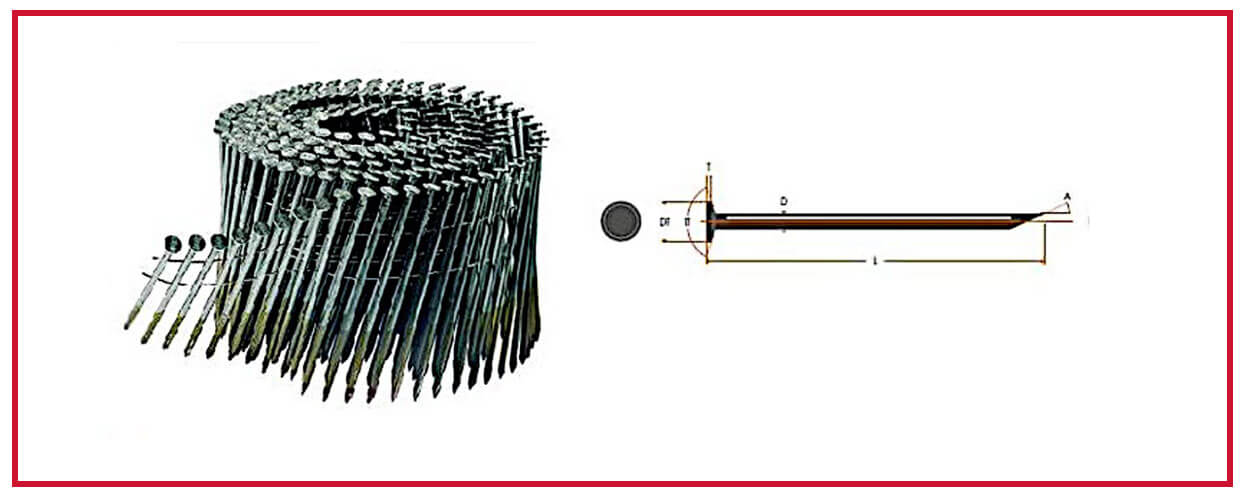

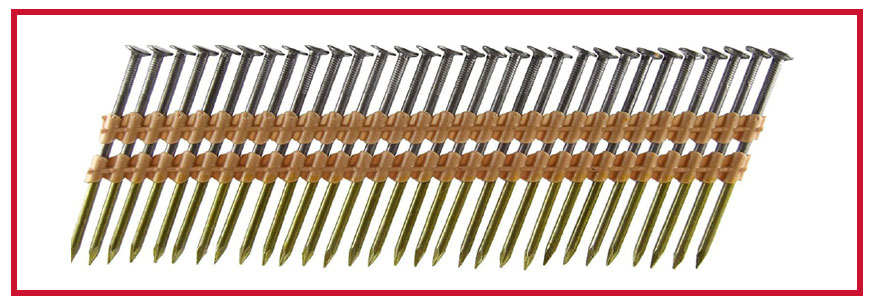

Coil nails come together collated in either wire or plastic in about 200-400 nails depending on the size of its head. They are designed to reduce reloading time and for high volume applications such as pallet making, crating, and fencing. Coil nails typically come angled between 15-16 degrees. Angled nails are critical designs aiming to reduce bulk and helps maneuver the tool in and around tight spaces. One of the most top durable coil nailers out there is the PN90 Coil Nailer.

All EVERWIN’s coil nailers come in at 15-degrees except our SCN66B Coil Nailer which drives zero-degree collated nails, perfect for siding applications

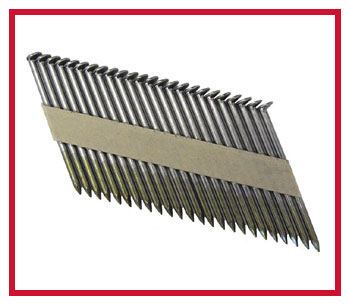

Stick nails come together collated in either plastic, wire or paper strips packed tightly together but hold fewer nails than coils. This is essentially better for tool weight, imagine holding a nailer overhead on the construction site for hours, a kg or two less makes a big difference.

You may wonder why the different collation types and materials?

Plastic collated nails are full round head nails angled at 21-degrees. Plastic is more weather resistant, so storing these strips should not be problem. However, in operation, plastic fragments from each shot will leave a mess behind for you to clean up. This mess can also lead to a slippery floor, an unwanted hazard on the worksite.

Wire collated nails are also weather resistant in damp environments but not in damp salt environments like on an island or near the sea where salt corrodes much faster.

Paper collated nails are the least weather resistant when it comes to storing, however, they do offer special pros the others don’t. For one, it leaves no mess or debris behind. Two, because its paper, it does not damage the coating of the nail compared to wire which is welded onto the shanks. Paper collated nails are also the most compact due to its 34-degree angle and clipped/offset heads. Our very own FSN3490 Strip Framing Nailer does the job better than anyone else.

If you’re undecided on a coil or stick framing nailer, check out our guide Coil vs Stick Nailers to pick the best suited tool for your needs.

Since we are on collation types, there is also glue collated stick nails which you’ll typically find on finish and brad nails. These are much smaller, ideal for delicate finish and furniture works.

Recommendation

Keep in mind tools made for a certain angle with only work with the same angled nails. So if you get your hands on a FSN2283 Strip Framing Nailer, then you’ll need a 21-degree stick of nails, but if you get a FSN3490 Strip Framing Nailer, which is also a 90mm Framing Nailer, you’ll need a 34-degree stick of nails. Wrong combinations of tools and nails often result in jams and malfunctions, so be sure to read your tool’s guide or consult your approved tool dealer.

With that said, we must also emphasize the importance of using the right tool for the right job. It all boils down to how much power you need to drive your fastener, the length of fastener, whether you need high volume? Or a lower weight tool? And your local building codes you need to abide. We’ve done our best to simply our comprehensive list of tools By Application Intended and By Fasteners Specification. Check out our website and best of luck on your next project

About EVERWIN PNEUMATIC

EVERWIN® was founded in 2012 by a group of American and Taiwanese pneumatic tool experts, each boasting decades of experience and success in the world of pneumatic fastening. They founded the company with one shared goal in mind— to “build a brand the fastening industry can rely on for consistency and efficiency”. EVERWIN quickly garnered recognition as a premier brand for industrial fastening tools. With strong roots in the industrial market, EVERWIN has a different take on construction nailers and staplers from most price-driven manufacturers today; and with a touch of innovation, its 2017 and 2018 product introductions earned EVERWIN back-to-back Pro Tool Innovation Awards