How a pneumatic nail gun works

Let’s nail down its firing mechanism: How a pneumatic nail gun works.

From arm-powered hammers, tediously pounding away iron nails into wood to automatic nail driving machines. Today, automatic nail driving machines ease the heavy-duty labor of driving nails with maximum efficiency and minimal effort. While there are different powered machines in the market, one of the most popular is the pneumatic nailer. Compared to newer technology such as the battery-powered nailers, pneumatic Nailers are still preferred especially on industrial job sites whereby speed, consistency, smaller size, and lower cost are priorities. However, battery-powered nailers do have their place where portability is preferred. Neither one is yet ready to displace the other completely anytime soon. Both work incredibly well, increasing productivity and cutting job times in half. For now, we focus on the mechanisms of a pneumatic nailer.

What is a nail gun?

Pneumatic means “operated by air under pressure”. So usually, a pneumatic nail gun would be connected to a separate air compressor which generates a constant supply of compressed air to apply the driving force behind each fastener. While there are many different types of pneumatic nailers, each for different applications, most work quite similarly.

If we would take a skill saw and dissect a pneumatic nailer, inside we would find a sliding piston assembled inside a cylindrical body. There is a head valve just above the piston and a long driving blade below it, called a driver, that acts as a hammer. At the end of the driver is where it hammers the nail’s head. This piston is quickly pushed up and down by compressed air moving from a series of air chambers and valves.

Let’s take a closer look at what happens when the trigger is pulled:

-

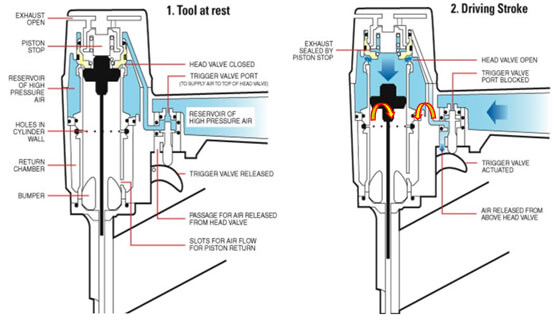

1. Tool at rest

High-pressure air from the compressor flows directly through the air reservoir around the bottom of the head valve and through the trigger valve channel above the head valve. So, both sides of the head valve have equal air pressure, however, the head valve also has a spring that pushes it down to keep more pressure above it so that it is pressed against the seal until the trigger is released.

-

2. Driving stroke

When the trigger valve is actuated, pressured air is then released from above the head valve. With greater pressure below the head valve, it pushes up causing air to flow into the cylinder, and air directly from the main reservoir moves to the area on top of the piston driver forcing it down.

-

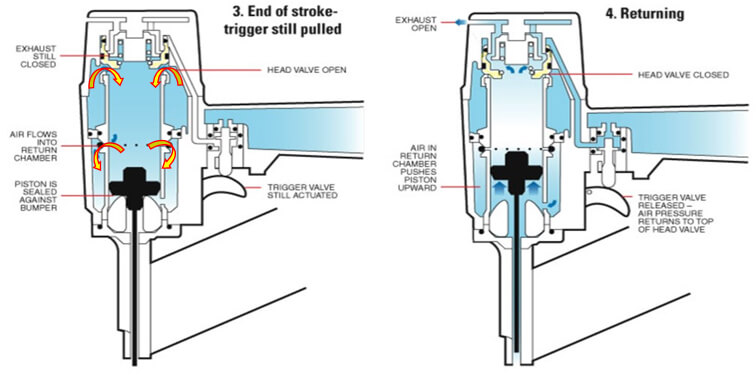

3. End of stroke trigger still pulled

The compressed air forces the piston fully downward and drives the fastener into your material. As this happens, air that was in the cylinder on the downward stroke pushes through a series of holes into a return air chamber where pressure builds up.

-

4. Returning

When the trigger valve is released, air pressure returns to the top of the head valve pushing it down and sealed again. With no more pressure from above the piston, the air from inside the return chamber pushes the piston back to its original position and pushes any remaining air from above out through the exhaust opening.

So essentially, when the air pressure above the piston head is greater than below it, the piston is forced down, driving the long blade with it, firing the nail through the barrel and into the material. The same goes for the return of the piston, as the pressure below the piston becomes greater than above it, it pushes the piston back up to its starting position. This sequence is called a cycle and just to give you an idea of how fast that is, here at Everwin some of our faster pneumatic nailers can do upwards of 20 cycles per second.

Keep in mind that despite the many brands out there, most pneumatic nail gun mechanisms work quite similarly. We hope that this information can be useful for any beginners looking to diagnose their pneumatic nailer/stapler if it isn’t operating properly. With that said, for the most part, pneumatic nailers work incredibly well, that’s why it is preferred for industrial work or even more serious household projects. Once we understand the power of its firing mechanism, we should be able to maximize its productivity and boost safety.